Project Name 05

Skills and Tools:

LEAN Methodology | 5 WHY Analysis | Pareto Analysis | Cross-Functional Leadership | Process Mapping | Stakeholder Influensing

90%

Shipment Success Rate

$100k

Saved Annually

40+

SKUs Launched

This is a paragraph. It is connected to a CMS collection through a dataset. Click “Edit Text” to update content from the connected collection.

SITUATION

New coffee machine launches at Philips were plagued by preventable delays that halted shipments for weeks.

Critical errors like labeling one of the key features as "milk breast pump" instead of "milk frother" (on a coffee machine!) or missing regulatory information created extra reworks at the local warehouses, delays in shipment deadlines, and, consequently, damaged retail partnerships.

Additionally, poorly translated manuals were creating confusion amongst consumers and damaging brand perception. With over $100K lost annually and with 50+ SKUs on the roadmap for release in the coming 3 years the broken process was undermining brand credibility with retail partners and market momentum.

TASK

So, the task seems clear: transform the new product introduction (NPI) process to eliminate costly rework cycles on both sides: local warehouse and global backend and restore retailer and consumer confidence. The goal was clear: achieve consistent, error-free launches while reducing localization costs and accelerating time-to-market. Success would be measured by shipment success rates, cost savings, and stakeholder satisfaction across markets.

ACTION

DIAGNOSTIC & ROOT CAUSE ANALYSIS

I started with a comprehensive LEAN diagnostic to uncover systemic breakdowns in the NPI process. I mapped the full product journey from R&D to market launch, conducted 5 WHY workshops to identify bottlenecks, and performed Pareto analysis to identify the most critical points contributing to failures.

The investigation revealed a lack of end-to-end ownership and any coherent process of which all involved parties are aware related to aligning documentation and assets with highly-regulated markets. Each department operated in silos without visibility into downstream impacts or accountability for final outcomes.

ACTION

CROSS-FUNCTIONAL SOLUTION DESIGN

The first challenge was to onboard all relevant stakeholders on this project. In a complex matrixed organization this meant identifying critical steps for the NPI, and departments responsible for each of them on the HQ and local levels. Then, I influenced my market Management Team to advocate the HQ top management to allocate time and leaders for the project on their side.

Succeeding on this mission (that deserves a separate post!) I facilitated cross-functional workshops where market, R&D, Regulatory and Engineering teams developed the proper process flow, identifying responsible functions at each step, repositories of information, estimated the workload and set milestone timelines. But most importantly of all - we made this process transparent to all the functions involved.

This collaborative approach ensured buy-in while addressing each team's specific pain points and establishing clear accountability frameworks.

ACTION

IMPLEMENTATION & MONITORING

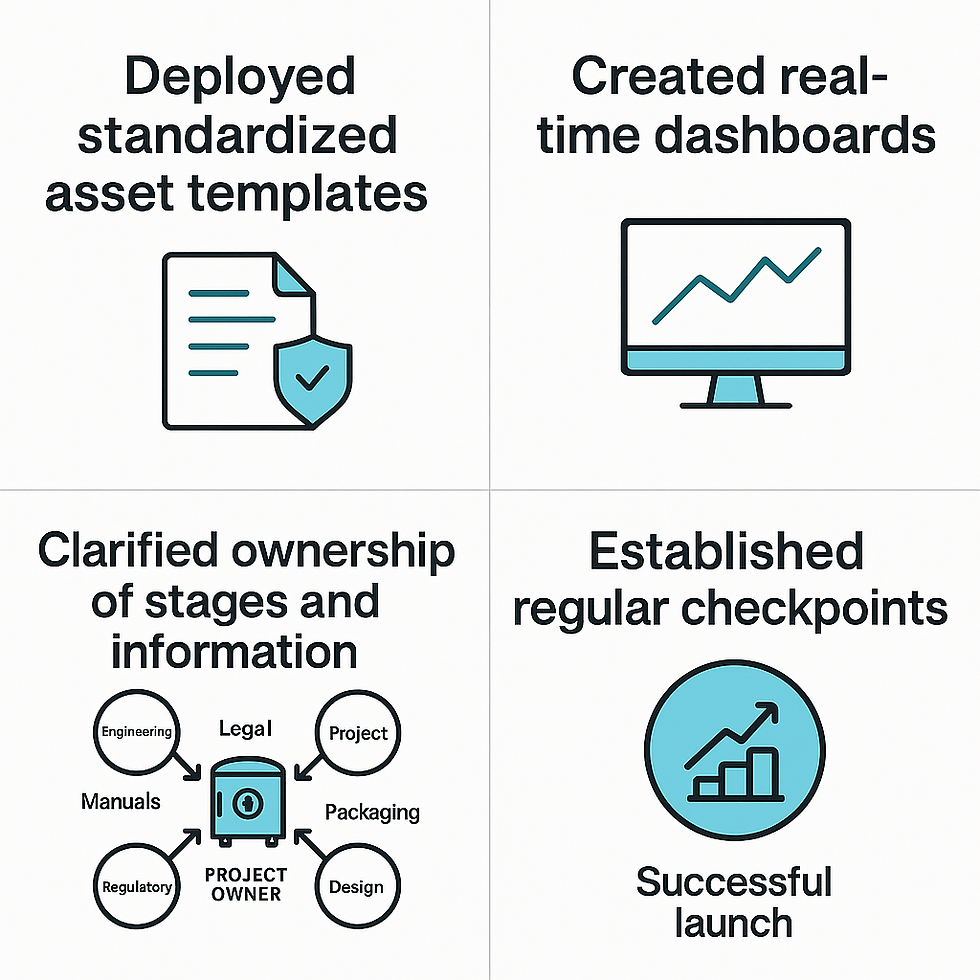

Deployed standardized asset templates with pre-approved legal and marketing content, cutting local market adaptation time by 35%.

Created real-time dashboards visible across all functions for milestone tracking and early issue detection. Established clear process line that kept stakeholders from various functions aware or the contact persons and owners of information.

Established regular checkpoint reviews and escalation protocols to maintain momentum and prevent regression to old habits.

RESULTS

The transformation delivered immediate and lasting returns that elevated our entire launch capability. Shipment success rates rose from 40% to over 90%, while annual savings exceeded $100K from eliminated rework cycles. Improved launch quality strengthened brand perception and retailer confidence, allowing us to save budgets on delayed campaigns and unfulfilled deadlines. Most importantly, the scalable process became a competitive advantage that supported our market leadership position.

90%

SUCCESSFUL LAUNCHES FROM 40% PRIOR

$100k

SAVED ANNUALLY ON LAUNCH REFURBISHMENTS

50+

SKUs LAUNCHED WITH THIS PROCCESS

IMPROVED